n a recent recovery, DriveSavers tackled a challenging RAID 5 failure. The 4x3TB array had entered Emergency Mode. The failure jeopardized 30 years of invaluable personal and professional data for the customer.

White Room: HDD vs. SSD Data Recovery

By Mike Cobb, Director of Engineering

Meet Ron Cen

Ron begins each workday by stepping across flooring topped with sticky material that collects contaminants from the bottom of his shoes on his way into a small changing room. After closing the door behind him, Ron suits up in a special hooded suit, face mask, gloves and booties before stepping across another sticky floor and through a second door into his workspace.

Inside the long, 2,000 square foot room, 33 fans spin loudly at a constant speed and bright florescent lights exaggerate the white color of the walls, floors, desktops and suits worn by Ron and his coworkers. Walls of computer monitors flash numbers and symbols as he walks past the open bodies of his subjects.

Ron is the Supervisor of Cleanroom Engineering at DriveSavers. He oversees a team of specially trained engineers who work alongside him to rescue lost data from masses of open, damaged hard drives in the largest, most advanced Certified ISO Class 5 Cleanroom in North America used for data recovery.

Open Subjects

Any failed computer or disabled device that uses a sealed hard disk drive (HDD) should only be opened and worked on inside a proper cleanroom—a laboratory free of dust, static and particulates—or the entire exercise may not only fail, but could render the data unrecoverable.

Cleanrooms are classified on several different levels, based on how clean the air is inside the space. The idea is to filter out microscopic matter like dust and smoke particles, airborne microbes and aerosol particles. These tiny materials could damage the delicate surface of the hard drive’s platters, which house important data.

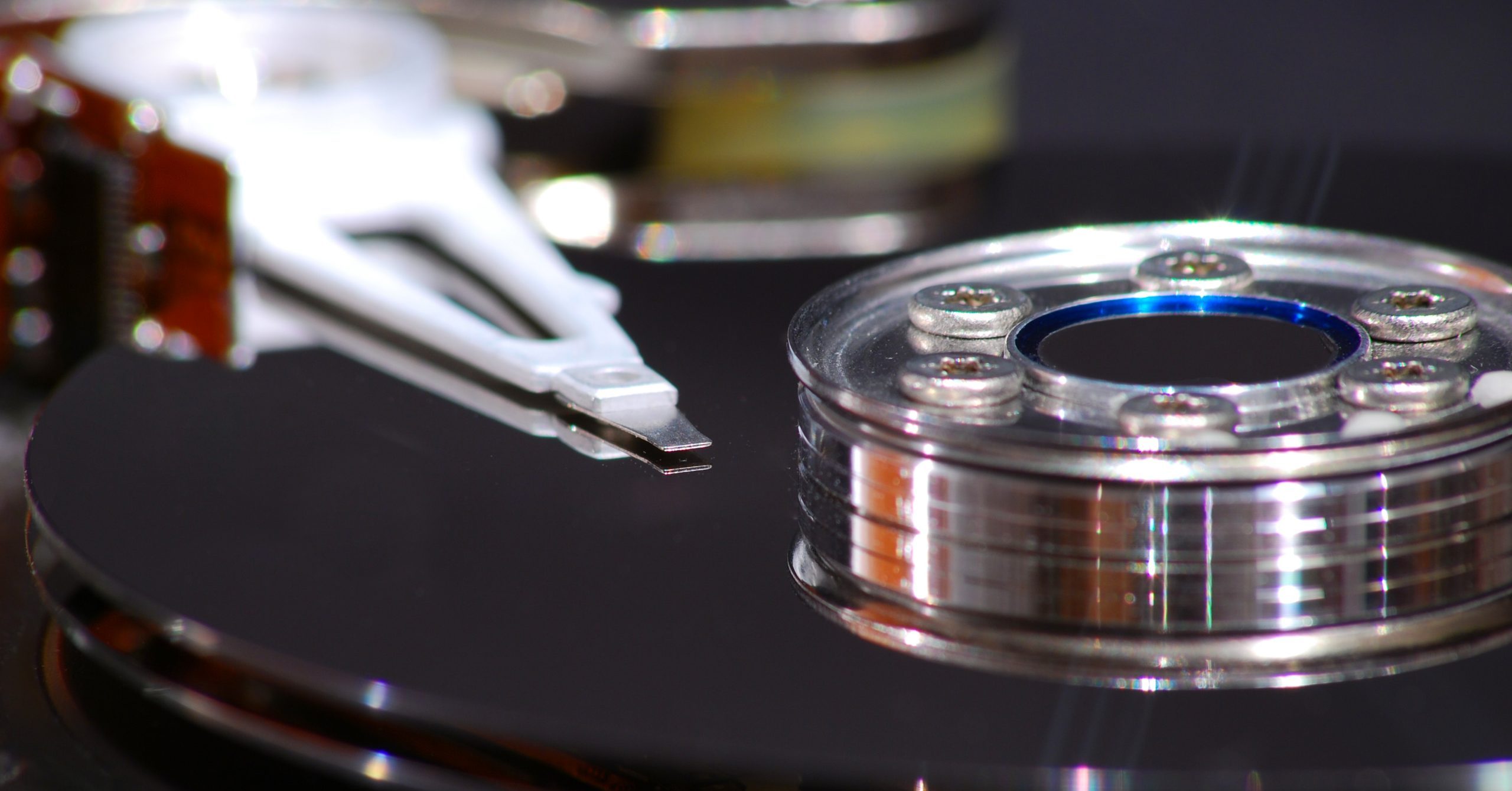

In an HDD, the read/write heads are attached to the end of an armature that swings out over the platters as they spin at speeds up to 15K RPM. Clearance between the surface of the platters and the heads is minuscule—about ten millionths of a meter, smaller than a fingerprint.

Particulate matter that comes to rest on the data-bearing surface of a spinning disk will be struck by the read/write heads as they attempt to do their job of reading and writing information to the device. When the heads, which float above the surface of the disks, strike any obstruction, then there is going to be damage that may cause permanent data loss.

It doesn’t take much time for this to happen, since the disks can move at speeds of more than 60 mph. Hitting a microscopic dust particle would be equivalent to a car hitting a speed bump while traveling at excessive speed.

The cleanroom at DriveSavers is designed to protect drives and give our engineers the highest probability of a successful recovery.

For more details, explore these articles:

- Take a virtual tour of DriveSavers, including our Certified ISO Class 5 Cleanroom.

- Inspect our cleanroom’s ISO Class 5 certification.

- Discover the dangers of microscopic particles in data recovery.

Meet Angel Ortiz and Jim Alcott

Angel and Jim are also both engineers at DriveSavers. You can find them with their faces buried in microscopes and other specialized laboratory inspection tools that are used to perform microsurgery on solid state storage devices (SSDs). But their work environment is entirely different than Ron’s.

Music fills the air rather than the whir of fans. While Angel and Jim do practice contamination controls at their workstations and wear standard lab safety gear like glasses, gloves and antistatic grounding wristbands, they are able to wear their normal street clothes. There are no special suits, hoods or booties. There are no sticky floors. Unlimited coffee and a staff kitchen are just around the corner.

Why don’t Angel and Jim need to work in the same type of pristine environment as Ron?

Angel and Jim are both data recovery engineers like Ron; however, unlike DriveSavers cleanroom engineers, they work on devices that use NAND flash and other solid state memory to store data. While flash media devices—like SSDs, flash drives, smartphones and memory cards—are all manufactured in controlled environments, they do not necessarily require a cleanroom setting for data recovery. Because solid state components have no moving parts or exposed media substrates, they are generally unaffected by the microscopic airborne contaminants that can destroy data on traditional spinning disk HDDs.

HDDs are magnetic, mechanical devices that rotate at insanely high speeds with nanoscopic tolerances that must be maintained between components, all while fighting the laws of physics on heat, vibration and friction. The smallest interference may result in the death of your drive and the loss of your data. SSDs operate on the same nanoscale, but are not prone to the same contamination-related issues. Their challenges are of an entirely different nature. For example, there are 760 capacitors in an iPhone 6 and every one of them is subject to failure, affecting the operation of the device and the ability to recover data.

Jim recovers data from smartphones that are not accessible due to logical or physical issues. Angel recovers data from SSDs that are physically damaged. They and their fellow flash memory data recovery engineers may not need to be inside the most advanced cleanroom in North America for data recovery (which the DriveSavers cleanroom is), but their jobs are equally difficult and specialized.

For more details, explore these articles: