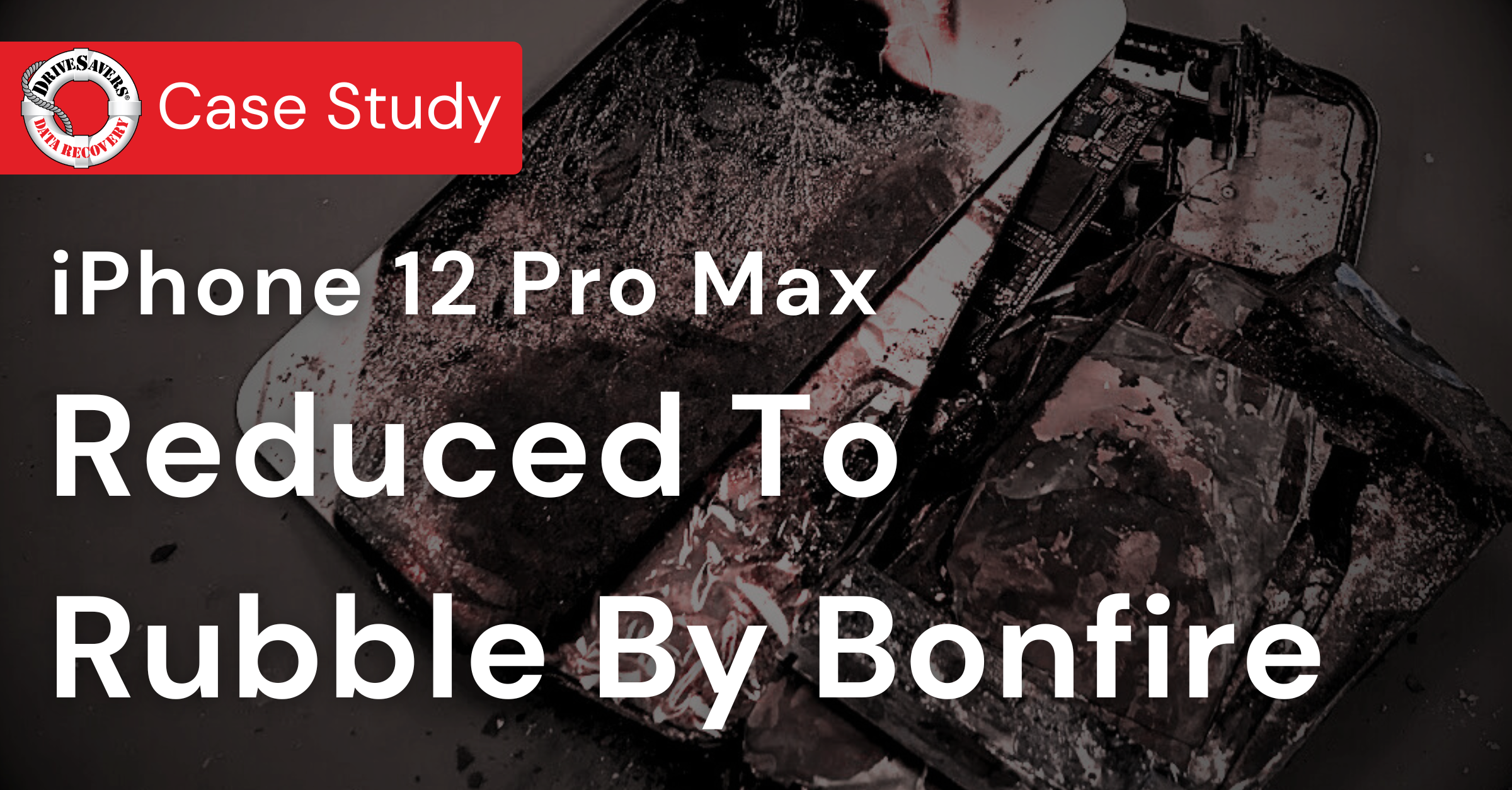

Oven-Baked iPhone Data Retrieval

A magnetized case, a sheet pan, and an iPhone that accidentally joined dinner.

Incident

One iPhone. One sheet pan. One preheated oven. Thanks to a MagSafe case, the phone hitched a ride into 400 degrees of chaos.

Damage

Thoroughly baked. Melted frame, bubbled screen, and a logic board that looked like it lost a fight with a rotisserie.

Goal

Rescue the irreplaceable data from an iPhone with extreme physical damage — family photos, favorite videos, and full text message threads.

Approach

Recreate a functioning environment by migrating the surviving, data-critical components from the scorched logic board onto a stable board platform, just long enough to coax out the data before anything else gave out.

Result

Complete success. All data recovered, encrypted, and intact — photos, videos, texts, and memories fully restored. The phone? Still smells like dinner.

It was a busy kitchen moment that could happen to anyone. With a meal in motion and family conversations competing for attention, the customer slid a sheet pan into the oven, not realizing their iPhone was magnetically attached to the underside of the pan.

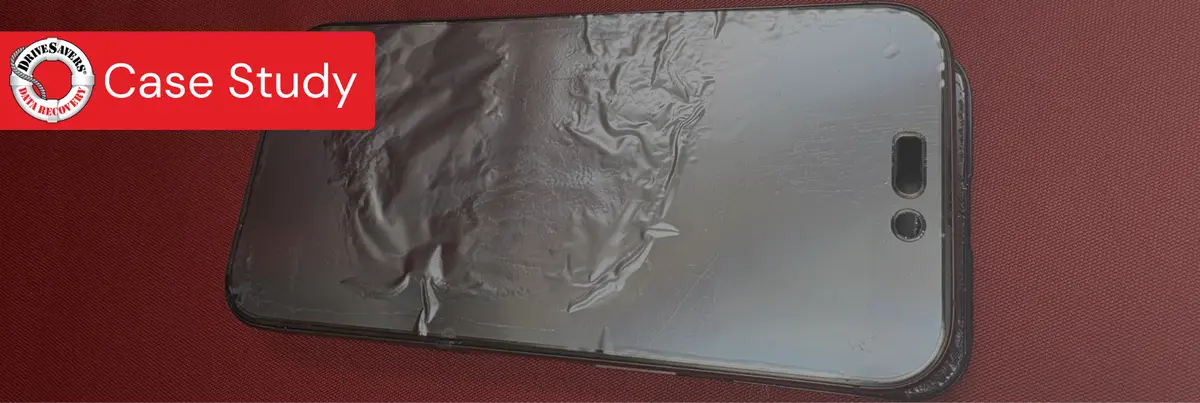

When the pan came out, the damage was obvious. The phone’s enclosure was softened and warped, the screen was clouded with small bubbles, and there was visible discoloration around seams and ports. Plastic near the buttons had curled, a light residue coated the edges, and the device would not power on.

What mattered was everything inside. Family photos, short videos, and complete message threads with attachments were now out of reach. The customer’s hope was simple. Get those memories back.

The oven baked more than the outside of the phone. The heat softened the frame, warped the board, and weakened the tiny solder joints that connect critical chips. Plastics curled, seals failed, and cables became brittle. The screen looked cloudy and had started to bubble, the case was a bit warped, and the electronics inside were stressed to the point that the phone could not power up or maintain a data connection.

Inside each chip is a thin slice of silicon — the die — mounted to a substrate and connected through microscopic bond wires. The assembly is sealed in epoxy or other protective coatings designed to survive normal operating heat. But an oven exposes the device to heat levels far outside normal conditions. At extreme temperatures, those protective layers can crack or delaminate, separating the silicon from its connections. In some cases, the die itself becomes exposed or fractures from thermal stress. If the die delaminates or fractures, the chip loses electrical continuity, making the data stored in that structure inaccessible.

The oven damage left the phone unable to boot or maintain a stable connection, which meant standard software-based methods weren’t an option. The logic board was simply too compromised by heat to operate, and the damage was too extensive to be restored through traditional board-level repairs. There was no scenario in which the original board could be made functional again. As a result, the only viable path was a controlled, chip-level reconstruction.

In this case, the engineers created a stable environment by migrating the surviving, data-critical components from the damaged board onto a verified, intact board platform. This is far more delicate than simply swapping hardware. A board that has been through oven temperatures can exhibit intermittent failures: it may start briefly and then crash, or establish a connection only to drop it moments later. The reconstructed board had to provide consistent power, clean signal paths, and enough stability for the device to identify itself, authenticate through the Secure Enclave, and maintain communication long enough to extract the encrypted data.

Maintaining a sustained session is another critical challenge, often where heat-related weaknesses reveal themselves. In this case, the reconstructed logic-board environment held steady, the secure connection remained intact, and the engineers were able to recover the customer’s data.

1

Chip-level reconstruction

Engineers migrated the surviving, data-critical components from the heat-damaged board onto a verified, intact board platform to recreate a stable environment.

2

Stabilize the logic board

The reconstructed board had to provide consistent power and clean signal paths so the device could identify itself, authenticate through the Secure Enclave, and maintain communication long enough to extract the encrypted data.

3

One sustained extraction session

Because heat-stressed boards may boot once or not at all, lab work is careful and deliberate—change one variable at a time, watch signal stability, stop at any sign of stress.

When a phone has been exposed to extreme heat—whether from a house fire, car fire, or an accidental “oven bake”—the logic board becomes brittle in ways that are invisible to the eye. Solder joints may be micro-fractured. Power lines may be partially shorted. Connectors might only make contact when the board is perfectly still. In this state, the device may be capable of one last clean boot… or none at all.

Every additional action—turning it on “just to check,” plugging it in, cleaning, or applying more heat—changes that delicate balance. A momentary wobble or a slight thermal expansion can turn a barely functional circuit into one that will never remain stable long enough to read the data again.

Successful recovery depends on getting the reconstructed logic board to run once, cleanly, and long enough to communicate without interruption. In the DriveSavers lab, diagnostics are methodical, deliberate, and measured: our data recovery engineers change only one variable at a time, look for signal stability, and stop immediately if the board shows signs of electrical stress. We install the logic board into a known-good chassis that provides clean power rails, reliable controls, and a protected environment for a single sustained extraction session.

If your phone was exposed to heat, do this:

Do not power it on or charge it.

Do not clean or heat it further.

Do not remove components.

Ship the device as-is to DriveSavers in protective packaging.

These steps preserve what stability remains and give you the best chance of recovery.

The takeaway is simple: do less before you do the wrong thing. Sending a burned or heat-damaged iPhone to DriveSavers as-is preserves whatever stability remains and gives you the best possible chance of recovering precious photos, messages, and memories.