SSD: What Happens When Connections Fail

Scenario: Unknown PCB (printed circuit board) Failure

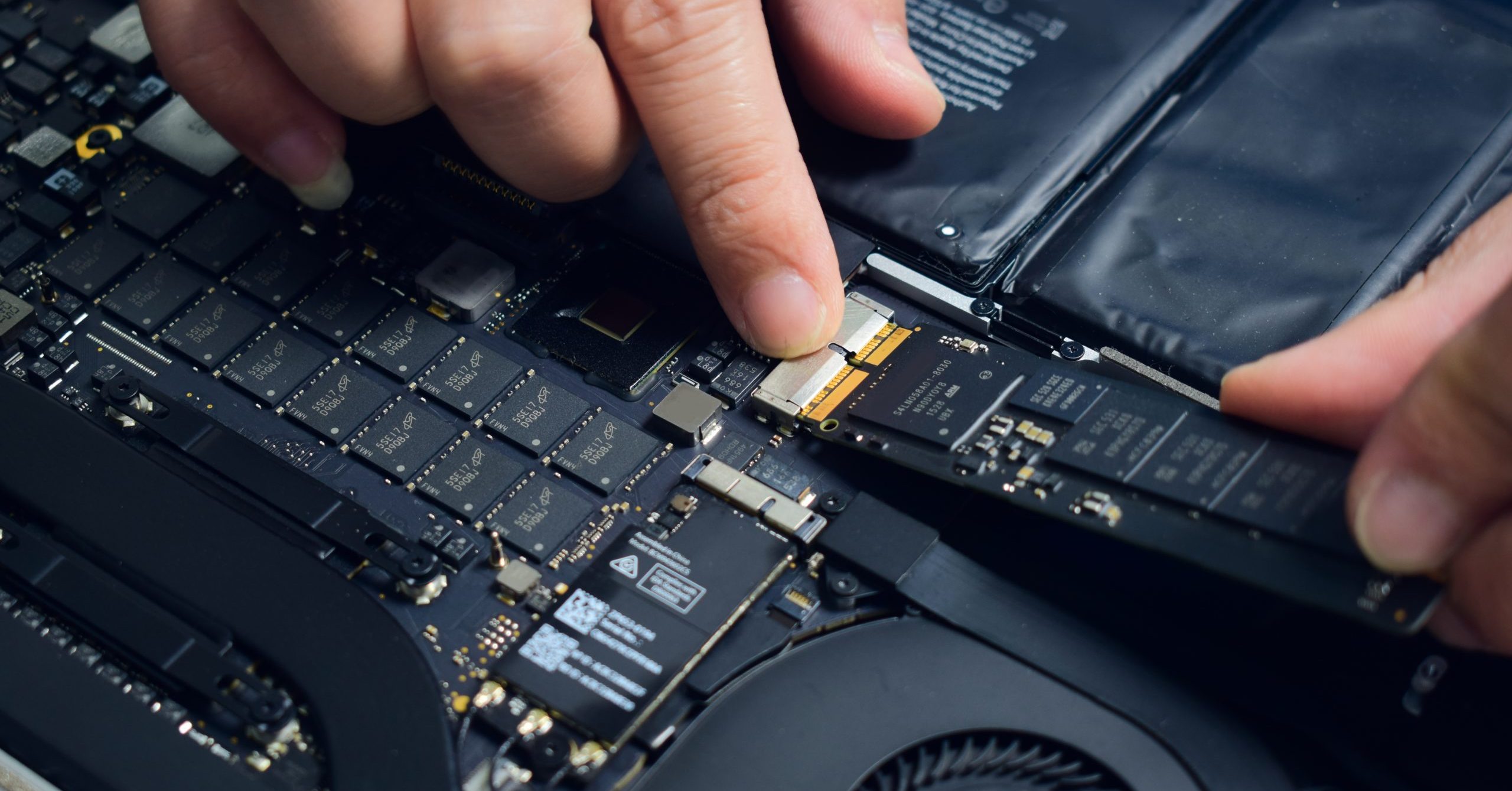

A solid-state drive (SSD) is simply a printed circuit board (PCB) with typically 3 basic types of chips soldered to it; DRAM, NAND and a controller (aka the “brain”). Each chip must be perfectly aligned with its specific location on the PCB, and a solid connection must be maintained at all times. If a connection is broken to any of the chips, the entire SSD may become useless and dead, otherwise known as “bricked.”

Causes

There are a variety of potential causes for lost connections or broken circuits on a PCB, such as:

- Manufacturer—Defective or inferior solder used at the time of manufacture could, over time, weaken in strength and therefore lose connectivity.

- Normal Wear and Tear—Thermal expansion and contraction that occurs with everyday use can eventually cause microscopic fractures in the solder, thereby interrupting a circuit.

- Physical Trauma—If the SSD is dropped, bent or otherwise mistreated, physical trauma could cause the board to flex and a connection to be broken.

As always, gentle handling and common sense can aid in preventing physical trauma to a solid-state device. Manufacturer errors and normal wear and tear are unavoidable.

Should an issue occur, it is important to prevent further damage that could make the data unrecoverable. Be sure to properly pad the device when packaging it for storage or delivery. Do not store the device where there may be dramatic temperature changes.

Or, to truly avoid any data loss, regularly back up working storage devices.

What Happens at DriveSavers

When DriveSavers receives an SSD with PCB issues, we trace every critical circuit and test all voltages to see if we can determine the root cause of the failure. In some cases, we remove and replace certain chips and in other cases, work to repair the PCB with its chips in place.

This process to realign and reconnect the chips to the PCB is known as “reflowing.” This is very tricky work, because the temperature used throughout this process needs to exactly match the proprietary temperature profiles provided to DriveSavers by SSD manufacturers.

If the wrong temperature is used, we could either fail to flow the solder enough to create good connections or, far worse, cook the board making data permanently irretrievable.

For this work, we use a highly specialized device called a “reflow oven.” The reflow oven enables our engineers to “soak” (heat at the same temperature for a duration of time) and then “reflow” (resolder) an SSD at the precise temperatures required to successfully rebuild the connections without harming the device further.

Once connections are temporarily reconnected, our engineers are able to make an image of the drive from which to recover data.