Linus Tech Tips: REAL Tech Repair – Linus Swaps Hard Drive Actuator!

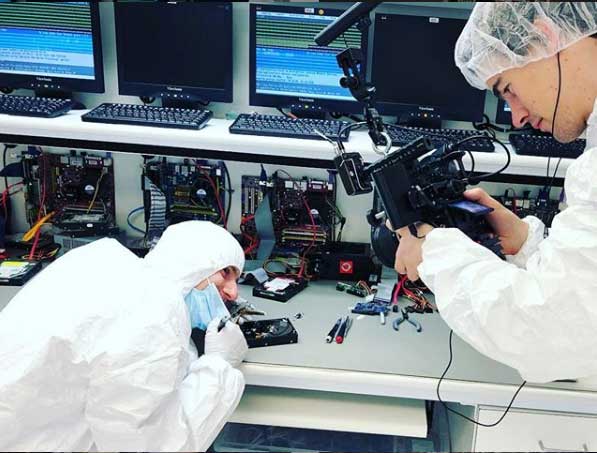

Linus: Okay. So you guys aren’t gonna believe this. We’re here at DriveSavers. These guys—they recover data off of drives, phones. The cleanroom’s over here. Basically, if it’s got data on it, these guys recover it. And they turn to me—they’re like, “look, we know you’re not here for very long but—I mean, we don’t normally do this as part of the tour—do you want to get—do you want to get suited up and do you want to rip apart a hard drive and do an actuator swap on a real hard drive in a real cleanroom?” And I’m like, “what kind of stupid question is that?”

Help, Pelle! I’m trapped in a cage! [pounds on glass door] Oh, we’re making a face. Okay, you know I’m just gonna—I’m just gonna be a nice YouTuber.

So inside here, it’s certified to be less than a hundred thousand point one micron particles per cubic meter of air. So it’s, like, ten thousand times cleaner than regular air. Oh, this is hot! Here we go. Well, that’s a heavy door.

So the whole room is positively pressurized. They’ve got, I think, it’s thirty-five fans running pushing air constantly downward. Look at that—look at this stuff! SSD, PCB… You know—no big deal. It’s freakin’ crazy! One and a half terabyte forensic, one terabyte target, two terabyte targets…Dang, this place is big!

Ron (DriveSavers data recovery engineer): How’re you doing?

Linus: Hi. I actually don’t know where I’m going. Cool—is this my station?

Jon (DriveSavers data recovery engineer): It’s gonna be your station. Yes.

Linus: Sick!

Jon: Have a seat. Come on up.

Linus: Thank you. Is this like a special cleanroom chair?

Jon: It is. They are all Class 100 (ISO 5).

Linus: Wait—I’m okay. It’s really slippery. Okay, maybe your suits are, like, better than mine but, like, I’m serious. Okay, okay. So, yeah. “This guy can’t even sit in a chair. How’s he gonna fix a hard drive?” Look—some of us don’t do data recovery every day.

Okay, he’s like, “this is the most boring part.”

Like, if I bleed in here is it, uh, there’s a contamination problem? In here, the theory is that it is so clean that I don’t need to seal the drive back up, is that right? Like, can I just run it open?

Jon: Correct.

Linus: Can we run this one without the lid on just to show it doing it?

Jon: This one, we cannot.

Linus: We cannot.

Jon: This drive will not run without the lid on.

Linus: Really? It just has, like, a sensor or something?

Jon: No, it has a little nub on the lid which puts a little bit of pressure on the actuator to keep it down so it keeps it level.

Linus: Ooohhh…Interesting. So, it’s not just…it’s not just a pretty face.

Jon: No.

Linus: The lid is actually functional.

Jon: Correct. So what you see here, this notch right here sits on the actuator right here.

Linus: Oh, wow—so it actually holds the entire actuator assembly down.

Jon: Well it just gives you a little pressure. Correct.

Linus: Oh, interesting. So, check this out. So, you’ve actually got four read/write heads because each of these platters can store data on both sides here.

So, what else can we say about this? So…so this guy right here holds these in place when it’s off.

Jon: Correct. This is what we call the “off platter parking ramp.”

Linus: So the read/write heads actually, like, are basically, like, they’re flying over these spinning platters. And these are going at, you know, up to 7,200 RPM these days. They used to go higher in some cases, but on a consumer drive these go up to 7,200 RPM and it’s basically like that—like a fly flying around in a hurricane, like, twelve inches off the ground. Like, it’s, like, it’s stupid. So, anytime you’re not actively reading or writing data, you want them, like, out of the way because if these contact there then you gotta send your drive to DriveSavers, period. And anything they touched is—they ain’t getting that back. Actually—that’s one of the scenarios where you might have to do what we’re about to do, which is an actuator swap, where if it accidentally makes contact the metal shards inside are so damaging that they could just tear apart these tiny fragile heads.

Okay. Hit me with the next step.

Well, it doesn’t say “do not eat” on it, but that is definitely desiccant and you definitely shouldn’t eat it. You should’t eat anything in a hard drive.

This is…my hands are shaking. That’s as steady as I can hold it. I’ll just get some two-handed assistance in there. Thank you. All I would have to do is drop this screw conveniently nonferrous. Oh, probably for a reason—there’s magnets in here. Duh!

Do people typically get this right on their first try?

Jon: Mmmm…Negative.

Linus: Cool. All right. Well, I’m excited, then. I want to do it.

You can pop that up. Yep.

Jon: Jiggle it loose.

Linus: Okay.

Jon: Alright is that?

Linus: Yup. Oh, yeah.

Jon: Cool. Alright. Let’s put that aside over here.

Linus: Yeah.

Jon: Next step, you are going to move the actuator stopper.

Linus: Whoa! You can really feel it, like, when you—oh, right. Like snaps into place there. Okay. And the stopper is this black guy right here, right?

Jon: Correct.

Linus: Okay.

Jon: You are gonna hold that right there without letting it fall off.

Linus: Yup.

John: And get this transport comb. And keep the heads separated, which is a version of this that we had made in-house ourselves.

Linus: Very cool.

Jon: So, what you are going to do, is keep that—slide that between there and try to get the actuator assemply off.

Linus: So, did I kill it?

Jon: Not yet—not that I know of.

Linus: Is it probably dead now?

Jon: Possibly. But let’s…You know what? Let’s let you continue with it like this first.

Linus: Okay. Does it matter which way you go?

Jon: No. You want to bring that off close to the edge a little bit.

Oh! Too far.

Linus: Oh!

Jon: Right there’s good.

Linus: Crap! No—they touched.

Jon: Did they?

Linus: Yeah.

I am sweating up a storm in here. This is so stressful!

So, you’re not putting the bottom one in, one.

Jon: I am in.

Linus: No—you’re the bottom one is on the very bottom.

Jon: That’s what I’m tellin’ ya.

Linus: Oh! No—I didn’t. Yeah—I didn’t get that. I thought they all had to go in one.

Jon: Oh, no. Yeah—the bottom one goes in one.

Linus: That’s why. Ugh.

Jon: Let’s try it again. Sorry about that.

Linus: Okay.

Well, if you’re guys’ goal was to make this look hard and like we should let professionals do it, then mission accomplished, I suppose.

Sure. Whatever. No problem. Can I have the pliers? I’m weak.

Jon: And hold the magnet at the same time because all of it has to come out at the same time.

Linus: Yeah—I gotta switch hands. I didn’t think this through.

Okay. Ah! Where do I put it?

Jon: Just place it straight down on the table. ESD mat—no worries.

Linus: Okay.

If I just wanted to know for sure if I killed it, could we try it?

Jon: I can tell you right now that we did.

Linus: Oh.

Jon: I see the head stack is bent.

Linus: Uh, oh.

Jon: The tip of the head is bent which creases upward like this. So, they should lay flat out this way. Right now, it’s laying flat this way and you have it coming up like this.

Linus: Here—have a look at that, Pelle. That’s the bottom one—it curls up a bit.

Jon: It curls up. What that is going to do…When I put that into a good drive right now…

Linus: Okay. It’s gonna scratch up the bottom platter.

Jon: It’s going to scatch up the bottom platter on side zero.

Linus: So, now, when we started this video, the intent was to just take a platter out of a working drive, put it back in and demonstrate that it still worked. What we’re ending up with is that, in order to fix this drive, we need a donor drive because this is actually a very common failure. I mean, not an idiot opening your drive and bending your read head and write head or whatever, but just a platter crash.

Failed actuator assembly. Thank you. And I’m gonna try this again but, like, super more carefully this time. And I know how the combs work.

All right. I’m gonna try and be more organized about these this time. So, this is step one. I want to do it right this time. I don’t like failing at stuff.

So you’ve done—I was told over 50,000 of these?

Oh—new trainees—they got to do about 3,000 before they touch a customer hard drive.

Jon: Before they touch a live job.

Linus: Wow!

Okay.

Jon: There you are.

Linus: Yeah.

Jon: No, what we are going to do before you do anything else.

Linus: Yeah.

Jon: We want to label our donor drive.

Linus: Oh, okay.

Jon: Let’s pu a “DS” on there for DriveSavers.

Linus: Where?

Jon: Right on the magnet here, please—”DS.”

Linus: Isn’t that redundant if I put it here?

Jon: Yeah, but you know what? It’s better safe than sorry. I don’t want to give the customer back his wrong part.

Linus: Right. Okay.

Jon: Or swap the wrong actuator into the wrong drive.

Linus: Got it.

Okay. Let me think. Hold on. This guy, right?

Jon: No.

Linus: No? Oh—shoot. Hold on. Let me think. This guy.

Jon: Correct.

Linus: Great. Okay. Man—the pressure’s on! I feel like this is, like, you know, the ninth inning of the big game or whatever. Like I—yeah. Now I put on the comb, right?

Jon: No.

Linus: Oh, crap. Okay. Hold on. Do I take these out first?

Jon: Correct.

Linus: [sigh]

My arch nemesis—we meet again.

Jon: Not quite yet.

Linus: Oh. Damn it! Hold on.

And I gotta hold this, right?

Jon: This.

Linus: While I do it?

Jon: This.

Linus: That one.

Jon: Actuator arm The e-block.

Linus: Okay.

Ah! Mr. Comb—we meet again.

Okay. Did I get it?

Jon: You’re good. You’re gold!

Linus: [sigh]

Oh, my god. Okay. Now, what?

Jon: Now, put that down on the side.

Linus: On its side? What does that mean?

Jon: Just flat on the table somewhere.

Linus: Okay.

Okay. You watched it. What do you think are my odds?

Jon: Ahhh…I think you got a pretty good chance.

Linus: Come on. You got…Don’t…Don’t…Don’t cheat me here. You gotta give it to me out of a hundred.

Jon: I’ll give you maybe a sixty-five.

Linus: Sixty-five?!

Jon: That’s kinda high.

Linus: Sixty-five is high?!

Jon: Sixty-five is quite generous.

Linus: Oh, well that’s not that good. Okay. What’d I do wrong, specifically? Just a lot of wiggling?

John: Yes. A lot of wiggling. The comb, when you were moving the actuator arm off the donor drive…

Linus: Yup.

Jon: That’s basically it. But, like I said, a lot of people, before they touch any live drives, it’s typically three-thousand swaps before they get to touch a customer’s job.

Linus: Right. Okay.

Jon: This is one of the reasons why.

Linus: Right.

Oh, man. My hands are still shaking like crazy. I would say I’ve never been more stressed to find out if a hard drive works but I definitely have. Anyone who’s seen the Wanek server video will know that.

It’s there! Okay. So, it’s detected but that doesn’t tell us that much, does it?

Jon: It tells us…That’s a great step.

Linus: Okay.

Oh, enter’s okay. But would K work? Theoretically, yes—right?

Jon: I would assume so. Let’s try it.

Hey!

Linus: Hey! You learned something today, too.

Jon: Yes, I sure did.

Linus: Hell, yeah man! Oh, what do you guys think? Okay, okay. No cheating. If you’re gonna leave a comment on the video guessing whether I got it or not, you have to do it now. You can’t do it after. That’s cheating. Wait—we didn’t clean the platters. Does that matter?

Jon: That’s okay. We’re in a cleanroom…

Linus: All the waiting! Wait—hey, hey!

Jon: And we’re imaging.

Linus: Is that good?

Jon: That’s good. Green is good.

Linus: Green is good!

Jon: So we are imaging right now. So, it is telling me it’s imaging a three terabyte drive. That’s your total block count right here. We are writing to an eight terabyte target.

Linus: Okay. So it’ll take nine hours.

Jon: Roughly. Approximately. Now, this is how it should work.

Linus: But we consider this a very good first step.

Jon: Very. This is excellent—for the physical aspect of the drive.

Linus: right? So, we saw…We’ve seen no even pink so far. No yellow…

Jon: No red, no yellow as of yet—as of yet.

Linus: Okay. Get a b-roll of that! B-roll of that.

So, there you have it, guys. We’re only 0% of the way through, so, you know, it’s hardly completely conclusive but we are tentatively calling the operation a success. Which is really exciting. It’s all green so far. However, I do need to be very clear that this was a best-case scenario. We had two working drives that had never been opened before. So even though I personally broke the heads on one of them, we knew that the rest of it was good—there was no firmware corruption, there was no media damage, there was no heat damage or whatever else these guys might deal with on a daily basis. But I’m still really excited about it and I’m still really grateful that I got the opportunity to try this out.

So, thanks for watching, guys. If you dislike this video then you, frankly, kind of suck. But if you like this video, hit that like button. Get subscribed. Maybe consider checking out where to buy the stuff we featured. I don’t know hard drives. Also have a link to DriveSavers down there. Those guys were total badasses for bringing us in here. Also, while you’re down there, you can check out our merch store—has cool shirts like the one I’m totally not going to show you because it’s totally covered in this suit. And we’ve got a link to our community forum, which you should totally join.