Hard Drive Data Recovery: Microscopic particles can cause huge damage

Updated September 2018

Por Mike Cobb, Director de Ingeniería

When you need hard drive data recovery, be sure the facility has the proper industry certifications. Otherwise, the data you are missing from your hard disk drive (HDD) may be at a much higher risk of being unrecoverable or even permanently destroyed.

The Dangers of Microscopic Particles in Hard Drive Data Recovery

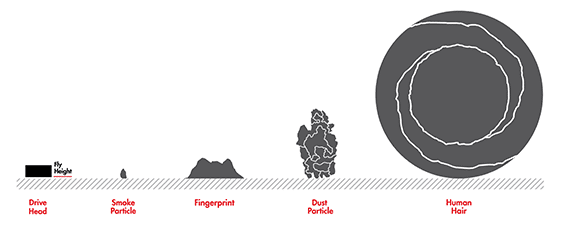

Cuando los platos de un disco duro giran a una velocidad media de 7.200 RPM, se crea un colchón de aire sobre el que el brazo del actuador y los cabezales de lectura/escritura flotan a sólo 3 nanómetros por encima de la frágil superficie de los discos giratorios. Esta altura de vuelo es microscópica, y resulta esencial para la funcionalidad de la unidad.

Extreme damage and data loss can result if any particulate matter (even something as thin as a human fingerprint) gets between the surface of the rotating disk and the read/write heads in a hard drive. Any foreign object could be struck by one of the heads, causing damage to the mechanism and destruction of data.

Se requiere: Sala blanca ISO clase 5 certificada

The hard drive data recovery company you choose should have a sala limpia in which disabled hard drives and other sensitive equipment can be inspected and worked on without introducing any additional risks of contamination, damage or data loss.

DriveSavers performs all hard drive data recoveries in a Certified ISO Class 5 Cleanroom environment with highly-filtered air containing no more than 100,000 particles greater than .1 micron in size per cubic meter. This controlled environment (laboratory) is 10,000 times cleaner than a typical room (non-controlled environment), which can have as many as 1 billion particles of this size per cubic meter.

Performing hard drive data recovery inside a Certified ISO Class 5 Cleanroom maximizes the opportunity for a safe and successful recovery.

Reducir el riesgo, aumentar la recuperación

Regular audits should be conducted to measure and certify the effectiveness of a cleanroom installation while it’s in use. Some data recovery companies with certified cleanrooms had their audits performed while the rooms being tested were unoccupied and not in operation. Particle counts may differ substantially while a cleanroom is actually in use and occupied with people.

Los técnicos de las salas blancas deben llevar trajes especiales, así como casco y calzado de protección contra la contaminación. Todos los accesorios, como papel y lápices para escribir, herramientas de limpieza, etc., están especialmente diseñados para reducir la emisión de partículas a la atmósfera.

How do you know if the audit was performed while the cleanroom was in use or not? Request the “Controlled Environment Testing Report” and look for “Occupancy State.” The status of the Occupancy State could be one of three: “as-built”, “at-rest” or “operational.” You want to see “operational.”

Nuestra Sala limpia con certificación ISO Clase 5 allows our engineers to work within the manufacturer-recommended limits of cleanliness during the recovery process. Take a moment to review DriveSavers current ISO Class 5 audit report, which we passed with flying colors while operational.

Have a sneak peek at the DriveSavers Cleanroom.

——–

Por orden de aparición en el artículo.

DISCO DURO: Unidad de disco duro

Cabezales de lectura/escritura: Los mecanismos que registran y recuperan información en un disco duro

Platos: Discos giratorios de un disco duro en los que se escriben y almacenan los datos.

Brazo del actuador: La armadura de la que se suspenden los cabezales de lectura/escritura sobre los platos en un disco duro.

Altura de la mosca: Distancia entre los platos y los cabezales de lectura/escritura de un disco duro: 3 nanómetros, es decir, aproximadamente 3/1.000.000.000 de pulgada.

Sala blanca: Un entorno de laboratorio personalizado en el que el aire se filtra continuamente para reducir la cantidad de partículas presentes.

Micron: Unidad de medida igual a 0,000039 pulgadas.